The higher cost of using permeable pavers, which require some expertise in both design and installation, is offset by their long life and potential savings on water.

The higher cost of using permeable pavers, which require some expertise in both design and installation, is offset by their long life and potential savings on water.Photo: Fred Adams Paving, Morrisville, North Carolina.

Permeable pavers solve problems and look good. Will they work for your business?

Pavers are an indispensable tool for designing outdoor living spaces. But if you’re not familiar with permeable pavers, you’re missing a growing market segment. Permeable pavers, also known as permeable interlocking concrete pavement (PICP), provide stormwater management by reducing runoff volume and rate, filtering pollutants and keeping water on site without the necessity of retention ponds. They’re key players in sustainability and low-impact development.

With additional design techniques, water collected from PICP can be retained in a cistern for watering plants and washing cars or directed to a rain garden. PICP has been used in Europe since the late 1980s, making its first appearance in the United States in the early ’90s. “Most landscape applications work with PICP,” says Fred Adams Jr., vice president of Fred Adams Paving in Morrisville, North Carolina. “Basically, they’re pavers with joints filled with aggregate so that water flows through like a grate from the surface to the groundwater.”

First used in commercial settings, the application of PICP in residential markets is growing. “More residential clients want ecologically friendly alternatives,” says Bill Gardocki, president of Interstate Landscape Company in Londonderry, New Hampshire, and a landscape construction instructor at the University of New Hampshire. “In some places, shoreline protection laws restrict the amount of impervious surfaces that can be located within a certain distance from any body of water, so clients are looking for acceptable options.”

Here’s what you should know about working with permeable pavers:

PICP is a system

Image courtesy of Belgard Hardscapes.

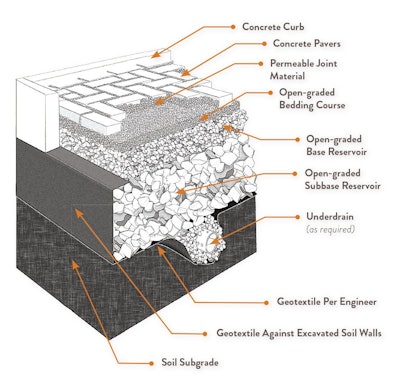

Image courtesy of Belgard Hardscapes.Permeable pavers are not standalone in function; they are part of a system of various layers and sizes of crushed stone. “The pavers themselves are not permeable. The water is not going through the paver; it’s going through the joints into the system below,” says Gardocki. “It’s important to get proper training because we most often see failures in the system when the contractor installs the wrong components beneath the pavers or fills the joints with sand or stone dust.”

Many municipalities now require certification to bid on commercial jobs. Look for classes offered at trade shows or throughout the year by paver manufacturers, or get certified by the Interlocking Concrete Pavement Institute.

Proper installation is key

Permeable paver installation differs from traditional pavers in several ways. First, the pavers are 3 1/8 inches (80 millimeters) thick vs. thinner non-permeable pavers, which are usually around 2 3/8 inches (60 millimeters) thick. PICP joints vary from 1/8 inch to ½ inch wide, depending on the volume of water that must be managed, and no sand is used between the joints so water can pass through.

Test digs are recommended to determine soil type and to aid in design particulars. For example, heavy clay requires different installation techniques from sand, says Gardocki. “You need to understand infiltration rates because you’re building a tub and asking water to go somewhere and not overflow but to filter through the system and regenerate groundwater.”

In most applications you’ll start by placing geotextile (to keep soil from working its way into the base layer) at the bottom of the excavated area, followed by a layer of stone sub-base such as No. 2 stone (thickness varies by design), then a 4-inch layer of open-graded base such as No. 57 stone, topped with a 2-inch-thick layer of bedding course such as No. 8 aggregate, then the pavers. Finish with a stone or cast concrete curb or manufacturer recommended edging product.

Joints between permeable pavers allow water to filter down through the system.

Joints between permeable pavers allow water to filter down through the system.Photo: Fred Adams Paving, Morrisville, North Carolina.

They’re durable

One of the biggest benefits of permeable pavers is that they can be used in a variety of climates and applications ranging from parking lots to patios. Permeable pavers average 8,000-psi compressive strength. “They have incredible durability,” says Jay Womack, director of landscape and ecological design for WRD Environmental in Chicago. “There’s no peeling and cracking like other surfaces.”

They also tolerate freeze-thaw cycles well. “Due to the use of open aggregates, there’s tremendous air space so water goes into air pockets and freezes, minimizing risk of heaving,” says Womack. Snow melts and drains due to the fact that the earth below is warmer than the ambient air temperature, so heat wafts up through the system. There’s no puddling so few deicing products are required, and the surface can be plowed like any other.

Maintenance is minimal

It’s a good idea to seek training on the installation of permeable pavers to ensure you’re exploiting all of the system’s advantages for your client.

It’s a good idea to seek training on the installation of permeable pavers to ensure you’re exploiting all of the system’s advantages for your client.Photo: Fred Adams Paving, Morrisville, North Carolina.

Initial costs to install PICP are similar to concrete or about two to three times higher than asphalt or traditional pavers. Costs are higher if stone must be hauled long distances, so finding a local stone supplier is helpful. “But you’re typically not competing against surfaces such as asphalt,” says Gardocki. “It’s usually for situations in which you require a pervious surface anyhow.”

Life-cycle costs are the biggest benefit. “The true savings is measured in the fact that you don’t have to build a retention pond and you’re actually creating water savings,” says Adams. In addition, you won’t need to seal or replace as often as other surfaces. Repairs are straightforward, as individual pavers can be removed and replaced.

Ongoing maintenance is simple. Keep debris from clogging the joints by vacuuming commercial surfaces once a year, or more often if grass or leaves have settled in the joints. For residential applications, gently clear out joints with a leaf blower on low as needed.

PICP is a potential niche market

“If you’re already doing hardscape, permeable pavers are a natural extension of your business. You’re using the same basic tools and concepts,” says Chuck Taylor, national commercial hardscapes adviser for Belgard Hardscapes. Permeable pavers also offer solutions for dealing with runoff, drought restrictions and flooding. “These environmental issues all become an opportunity for the contractor,” says Taylor.

While the popularity of permeable pavers is growing, especially in the residential sector, it’s still a wide-open market. “Not a lot of companies do installations well, so you will have an edge if you get the proper training,” says Womack. “But educate yourself so you can educate your clients. You don’t want to sell something you don’t understand.”