A decade ago, the thought of Doosan Bobcat being a part of the Consumer Electronics Show (CES) was almost a joke.

Today, now having attended three times, in 2020, 2022, and 2024, the company has become almost an expected presence at CES, poised to unveil another innovation that pushes the industry forward.

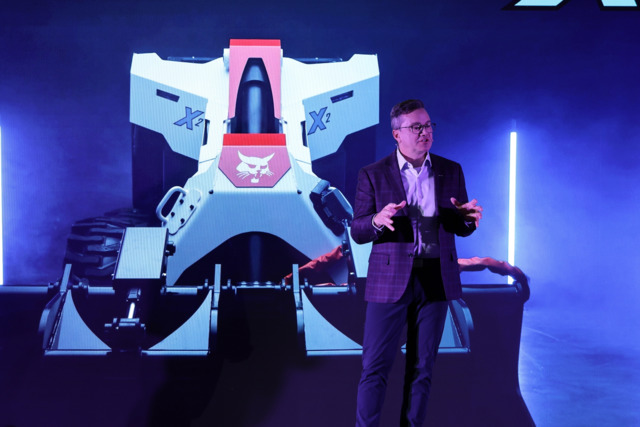

Leading the team of innovation engineers is Joel Honeyman, vice president of global innovation at Bobcat.

Before the company's first time exhibiting at the show, Honeyman, members of his team, and Bobcat CEO Scott Park attended to determine if it was something that fit with where the company was headed.

According to Honeyman, the CEO simply told him “Hey Joel, maybe we should have a booth.”

Those eight words from Park led to a rapid acceleration of the digital transformation of Bobcat. The company first appeared at CES 2020, showcasing Bobcat MaxControl and a diesel excavator.

“We've grown up each time and we really hit it out of the park,” Honeyman said, noting that Bobcat has since been attending every other year. “I’m proud of my team and what we’ve done. We’ve shown we belong at this show. If we are going to work in the global area of technology and attract partners, vendors, and even employees to work for us, I think we must show that we work in those areas.”

Bobcat’s presence at CES has not only been felt across the industry but has also borne fruit for the company.

Products and features included Bobcat MaxControl, Bobcat Machine IQ, Features on Demand, the world’s first all-electric compact track loader, the T7X, and much more have since hit the market.

To achieve its innovation goals, Bobcat has been involved in various collaborations, partnerships, and strategic equity investments with other companies, including Moog Inc., Viridi, Green Machine, LG, Agtonomy, Ainstein AI, Inc., and more.

Appearing regularly at CES has only increased the number of potential partners. Compared to five years ago, Honeyman said he is now constantly sifting through phone calls and emails from potential development partners or investors.

“We push the limit, and then we look to see what makes sense, and we go, okay, now, where do we start?” Honeyman said.

Having attended three times, in 2020, 2022, and 2024, Doosan Bobcat has become almost an expected presence at CES, poised to unveil another innovation that pushes the construction industry forward.Bobcat

Having attended three times, in 2020, 2022, and 2024, Doosan Bobcat has become almost an expected presence at CES, poised to unveil another innovation that pushes the construction industry forward.Bobcat

The future is now

At CES 2022, Bobcat unveiled the world’s first all-electric compact track loader, the T7X. Powered by a 62 Kw lithium-ion battery and battery management system, the machine carries a charge for up to six hours, which, when you factor in idle time, generally would make up an entire work day, according to Honeyman.

Continuing to evolve its electric product offerings, Bobcat introduced the S7X all-electric skid-steer loader at ConExpo 2023.

Like the T7X, the S7X is all-electric, powered by a 60.5-kWh lithium-ion battery. Nearly 95% of the parts of a T7X and S7X are the same, other than the undercarriage. All hydraulics have been eliminated, with each using electric drive motors and ball screw actuators for lift and tilt functions.

Significant efficiencies are gained from turning only four tires versus moving the tracks on a CT. As a result, with the S7X, the battery runtime increases to nearly a full eight hours, depending on the application. It was part of Bobcat’s display at CES 2024.

Both machines in their respective years at CES were recognized with multiple CES Innovation Awards.

Completed T7X machines are currently being shipped to Sunbelt Rental locations, and customers will have an opportunity to order them later in 2024. Production on the S7X machines is not expected to begin until 2025.

Another new electric and autonomous machine unveiled at CES 2024 was the AT450X, which combines Bobcat’s articulating tractor with Agtonomy’s software and embedded-computing technology to support emissions-free and autonomous operation of time-intensive tasks.

A pilot group of customers is set to receive the machines for testing and evaluation later in 2024. Conceptually, the software from Agtonomy could expand into other Bobcat products.

“Autonomy is autonomy at some base functions,” Honeyman said. “You're taking an input signal, saying that you're in a position in space; those things are universal. It doesn't matter if it's a car or one of our vehicles. A lot of it is applying it to the vehicle and giving those commands and having the vehicle be able to accept the autonomy commands.”

He said the "secret sauce" in the development process of autonomous vehicles is specifying the software solution for the vehicle.

Mowers, articulating tractors, and track loaders have three different types of operations and how you control them in an autonomous environment will be different. Bobcat is working on autonomous options with different partners in all three.

Like the T7X, Bobcat's first iteration of its all-electric, cab-less semi-autonomous machine, the conceptual RogueX, was designed as a track loader. It was unveiled simultaneously at ConExpo 2023 with the S7X.

Following the progression of the all-electric loaders, Honeyman’s team took on the challenge of making some design adjustments and presenting the RogueX2 at CES 2024.

“It's a similar overall concept to the RogueX but I would say we gave this one a little bit more aesthetics for the futuristic look,” Honeyman said.

Both concept machines explore the extreme of what an electric, autonomous machine might look like, and give contractors an option of using remote operations to access work in places where humans maybe shouldn’t go.

Generally, the company’s second semi-autonomous concept machine was well received, even getting praise from a former BMW design engineer who told Honeyman that it was “well done.”

The RogueX and RogueX2 machines are intended to provide a glimpse into how a future jobsite might operate, either autonomously or via remote positioning using Bobcat MaxControl.

“We want to show what’s possible,” Honeyman said. “It’s a playbook.”

The two machines are defined as being “semi-autonomous" based on applications where autonomy makes sense.

There are what some operators might call monotonous, repetitive tasks that they would love to eliminate. One of those is a basic lift and carry operation, such as moving pallets of bricks or other materials off a truck to a location on the jobsite. Bobcat receives a lot of calls from customers about whether such tasks could be automated.

"If you're a skilled loader operator, and you're doing fine finish grade work, lifting a pallet from point A to point B isn't the most exciting job,” Honeyman said. "It's not about limiting labor, but it allows your experienced operator to go do the fine-grade work using more complicated attachments for those types of applications that are much harder to make autonomous."

In late 2024, select loaders with the option of the Bobcat’s new collision warning and avoidance system will be available.Bobcat

In late 2024, select loaders with the option of the Bobcat’s new collision warning and avoidance system will be available.Bobcat

Eyes open

While there was excitement over the all-electric and semi-autonomous machines, Honeyman admitted that the biggest hit at CES 2024 was, by far, the company’s advanced display technology.

In partnership with LG Electronics, Bobcat is developing a transparent Organic Light Emitting Diode (OLED) touchscreen display that will appear directly on a machine's window. The prototype provides a transparent, engaging touch display embedded within the glass structure of the operator’s cab. The display, which operators can see through to also view the jobsite, can be positioned on the front windshield or a side window.

Currently, the transparent OLDE can be attached to the window, but in the future, the screen is intended to be embedded into the window itself, so it is the window. Work is still being done to make that happen.

“We have a lot more of those things to test out before we look at the mounting,” Honeyman said. However, several glass manufacturers have approached Bobcat with interest in collaborating on the final product.

For now, the priority is getting customer input in the field. Several machines will be going out to customers later this year to test and evaluate the concept of the transparent touchscreen.

“This will be the first time we have machines where we will put this out and we'll start evaluating,” Honeyman said.

At CES 2024, he said attendees were wowed by the concept. For his team of engineers, it just made intuitive sense to use the glass on the machines as a display because of all the available glass.

“For us and our competitors in construction or even in ag, there’s so much glass and very little space,” Honeyman said. “The challenge we have as a manufacturer is our operational displays can only get so big.”

Unlike cars, which have an entire dashboard that can be turned into a screen if needed, heavy machines don’t have that luxury.

His team took on the challenge of turning the glass into a touchscreen display and how to go about that. Four years ago, they started with the use of projectors, a concept that failed for numerous reasons. CES 2024 was the latest demonstration of the concept, which Honeyman said has come a long way in just the last six months.

“This one really looked like it belonged,” he said. “Now, if we take some things out to customers, I think it will help to drive some excitement.”

One new feature of the display that was not previously available was the inclusion of the augmented reality camera.

According to Honeyman, the camera will be fixated on the machine, and as you move, objects on the screen will appear in augmented reality so you can see where they are supposed to be spatially. This could include utilities or other objects you are looking to avoid on the site.

Plans are for future advancement of the technology to include grade and elevation options, which better illustrate to operators if they have dug too far or how much backfill might be needed.

“Just being able to give them directionally some things rather than someone have to go out to survey, or they got a laser grade or some other expensive piece of equipment,” Honeyman said.

Also, in late 2024, select loaders with the option of the Bobcat’s new collision warning and avoidance system will be available.

The system is designed to assist operators’ jobsite awareness, tracking the position, direction, and speed of objects relative to the machine. By using either the active or passive setting, operators can receive audible alerts or enable the machine to stop automatically upon detecting an object in its path.

It has been displayed quietly at a few shows and gone through customer testing and evaluation.

“I think that is going to be an interesting one once we launch because there are some customers, we showed it to early on that said they won't operate a machine without it,” Honeyman said.

A similar overall concept to the RogueX, the RogueX2 is designed as a cab-less, semi-autonomous skid-steer and has a bit more of a futuristic look.Bobcat

A similar overall concept to the RogueX, the RogueX2 is designed as a cab-less, semi-autonomous skid-steer and has a bit more of a futuristic look.Bobcat

Is this for real?

With its diverse mix of electric excavators, all-electric loaders, semi-autonomous concept machines, and genuinely futuristic touchscreen options, some contractors and competitors feel Bobcat has created some of these platforms solely for 'sustainability' and public relations benefits.

However, the company's track record of taking its innovations from concept to dealer seems to say otherwise.

“We're very passionate at Bobcat about getting these things out commercially,” Honeyman said. "We don't want to be the company that just shows things year after year, and then nothing ever comes of it."

Though no specific names were offered, the suggestion is clear that at least a few of Bobcat’s competitors engage more in that game of teasing and then either very slowly or never deliver on unveiled concepts.

“We don't want to be known as that,” he said. “We're demonstrating a collision warning and avoidance system, and it's going to be out there later this year. We're showing the OLED transparent touchscreen, and at some point, it's going to be out there.”

As new ideas are brought forward by Honeyman and his team, even if they are far-reaching concepts like the RogueX or RogueX2, ultimately, the idea is that even just some of the features on such futuristic machines could be applied to today’s Bobcat products.

"We think of it as what can we do for the operator now, while they're in the operator station, and then extrapolate how those technologies might help to create solutions in the future,” Honeyman said. “We're going to evaluate the whole package and look at what makes sense for commercializing for our customers.”

As an example, the RogueX machines each included an autonomous hardware and software kit. There are options to install those kits on existing track loaders.

"That's another way for us when we develop something on this far-reaching type of platform, then we can apply it and make it an option or a plug-in on a current product," Honeyman said. "Our strategy on a lot of our technology here is, why don't we just enhance the current machine because not every customer wants something new. We wouldn't want to burden every machine with a lot of extra technology they're never going to use."

He and his team take pride in showing off what they are working on at CES, ConExpo, and other shows with the ultimate intention of bringing the product to market. From the prototype stage, the next step is always a trial run and evaluation in the field with real customers.

Honeyman said some ideas go over very well based on customer input and some do not. Fortunately, the innovation team is never offended by the customers' opinions and instead takes the input to improve upon what they were doing and home in on a final concept.

From that point, the machine or features are analyzed to see what can be commercialized or fit into the company’s current lineup.

Looking ahead, Honeyman said one of the things holding back some development, and electrification specifically, is fast-charging options.

“Charging and battery technologies are getting better and better at an exponential rate,” he said. “The day that you can charge your vehicle in the same amount of time it took me to put gas in your vehicle, the world's going to change.”

Honeyman said that is the singular thing that needs to advance to change many of the viewpoints on electric vehicles both on and off-road.

From his perspective, as a manufacturer, Bobcat has been tasked by itself and its customers to eliminate emissions and be more sustainable. Electrification of some of the machines is one of the top methods to accomplish that goal.

“If you don't eliminate the engine, you're not eliminating one of the key factors that people have asked us for, and that was eliminating exhaust,” Honeyman said, noting that hybrid is an option but doesn’t address that key factor.

However, like several other heavy equipment manufacturers, he acknowledged that Bobcat is experimenting with hydrogen, fuel cells, and other fuel alternatives.

“Everything is on the table,” Honeyman said.

He emphasized that as a company, Doosan Bobcat has never made a statement that diesel is going away or that it is going all-electric as some companies have indicated is their intended direction.

“We’ve been very clear in our stance, it’s both,” he said. “We're going to monitor which vehicles and vehicle sizes it makes sense for, and we feel like we're in a very good spot to fit the needs of our customers.”

In addition, Honeyman recognized that some of this new technology is not for everybody.

“Many of these things are options,” he said. “We're going to make diesel hydraulic machines for a long time. However, we just got another call this week from someone saying ‘Hey, do you have this all-electric track loader? When can we see it? That's what we're here for.”