Cat’s RemoteTask remote control can be used in demolition, protecting operators from flying debris. The system will be available in January.

Photo: Caterpillar

RemoteTask – now available on Cat D Series skid steers, compact track and multi terrain loaders – allows operators to remotely control these machines with precision using a “belly box” control system. While remote controls are not new to skid steers, Caterpillar claims its system, developed with autonomous vehicle provider TORC Robotics, offers increased precision.

“It’s just like you’re in the cab,” says Bob Shoop, Cat product demonstrator/instructor. “In the past, there was a lag; you’d give a command and you’d wait for the machine to move. Now when you give a command, it responds immediately. The feel and response mirrors the operator controls of the machine itself.”

Remote-controlled machines shine when contractors need to deal with potentially hazardous tasks or environments, such as in demolition, where there’s a desire to keep operators away from flying debris. It also comes into play when you want unobstructed, precise operation, such as building fences and retaining walls in landscaping, or when cutting concrete or cold planing in paving.

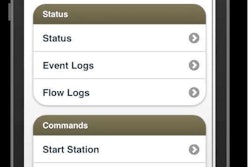

RemoteTask operates within the operator’s line of sight as far away as 1,000 feet from the 10-pound belly box. The RemoteTask controller is an all-in-one unit, says Cat, integrated with all work tool hydraulic controls, engine rpms, and creeper and 2-speed controls. To transfer from in-cab control to remote control, the operator steps off the machine, goes to the rear-mounted Remote Enable Interface box, uses his machine key to switch the remote control on, establishing signal with the transmitter, and watches for the top-mounted indicator light to turn green. (The remote control does not operate if there is weight in the operator’s seat.)

The RemoteTask belly box controls attachment hydraulics (including the quick coupler), engine rpms and the machine’s drive system.

The RemoteTask belly box controls attachment hydraulics (including the quick coupler), engine rpms and the machine’s drive system.Photo: Caterpillar

From that point on, he can control the machine remotely. Safety features on the belly box controller include remote control indicator lights for all machine warnings, alarms and faults; both vibration and audible buzzer warning signals; and an emergency stop button.

The machine stops within 0.5 seconds if the remote control signal is lost. Adding RemoteTask to a machine takes about an hour at a Cat dealer and includes installation of indicator beacons on top of the machine and a Remote Enable Interface box on the back of the machine. The Remote Enable Interface box contains a key switch that changes the machine from manual to remote and back again, service and ready LED light indicators and an emergency stop button.

Cat dealers have an exclusive marketing agreement to distribute and support the RemoteTask system, which can be transferred from one machine to another. The system will be available in January.