InfoHub’s hardware can work as long as a machine has a spark plug and a battery.

InfoHub’s hardware can work as long as a machine has a spark plug and a battery.Photo: Briggs & Stratton

This is part one in a two-part series. The sequel article will publish on TLC tomorrow.

Brake Landscaping & Lawncare, Inc. is like many other lawn care companies in that it is always striving to be as efficient as possible in every aspect of the business.

Yet unlike its competitors, the St. Louis, Missouri-based company has a new tool that has helped it improve on multiple levels. The company is one of the pilot users of Briggs & Stratton’s web-based tracking platform known as InfoHub.

Briggs & Stratton introduced the business solution back during the 2017 GIE+EXPO. It was originally the manufacturer’s idea to create a tool that would provide data on lawn care companies’ machine engines, but owners responded saying they were more interested in where their crews and equipment were throughout the day.

InfoHub was put to the test through 2016 and 2017, as more than two dozen lawn care companies tried the tech out in the field.

Brake Landscaping started using InfoHub in May 2017 after their dealer referred them to Briggs & Stratton as a candidate.

Increased efficiency

InfoHub consists of an Internet of Things device that can be installed on any piece of equipment with a spark plug and a battery. The data is sent to its cloud-based platform in real-time, allowing companies the luxury of tracking their crews and mowers from both their computer and phone.

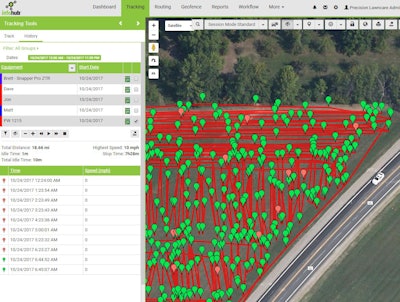

What makes InfoHub different from other tracking systems is that the system is tracking the pieces of equipment on a trailer and can notify company owners when the mowers are off, in transit or actively mowing. This allows lawn care companies to see mowing patterns and spot inefficiencies.

For Jason Rives, general manager at Brake Landscaping, before he had InfoHub, the only way he could know where his crews were and what they were doing on a job was if he physically went out to the jobsite to watch them mow himself.

Mowing patterns can show supervisors where inefficiencies are occuring.

Mowing patterns can show supervisors where inefficiencies are occuring.Photo: Briggs & Stratton

“It’s been definitely a wakening moment for myself, and the crews and our supervisors,” he says. “We think we’re doing things right and we’ve trained them to do certain things but when you have a job that requires 12 guys all day long, there’s millions of opportunities for them to be inefficient.”

He doesn’t believe that any crew is purposefully being inefficient, but without a way to see the bigger picture, it can be hard to spot when an employee has mowed the same turf three or four times while standing on a jobsite.

“Once we got into the program and noticed their habits and their patterns and we got in and worked with them and changed some things, they were knocking two hours off their day for 12 guys,” Rives says. “That’s a lot of labor, that’s a lot of manhours that are saved just by looking at the bigger picture from something I never would have been able to do before.”

Another efficiency aspect that InfoHub brought to light was the actual usage of equipment.

“I noticed that a brand-new piece of equipment that we bought for the crews to make them more efficient never left the trailer all day long,” Rives says. “They never used it.”

As it turned out, it wasn’t that the crew members didn’t want to use the new piece of equipment, it was just they weren’t accustomed to operating that type of mower. In response, the company went about training the crews more with the new equipment so they could feel comfortable running the new mowers.

According to Rives, last year the company exceeded its profit margin goal by 17 percent and all 15 mowing crews were profitable as well.

“I’ve never seen the efficiency numbers that we had last year ever in this industry,” he says. “It gives me an edge on my competition and it allows me to get maybe get a little tighter with my bidding knowing that I’m going to be efficient, and it allows me to pick up more profitable jobs in the future.”

Check back tomorrow for part 2 of this series, where we’ll cover how InfoHub has helped Brake Landscaping make the most of its employees and the additional benefits of the platform.