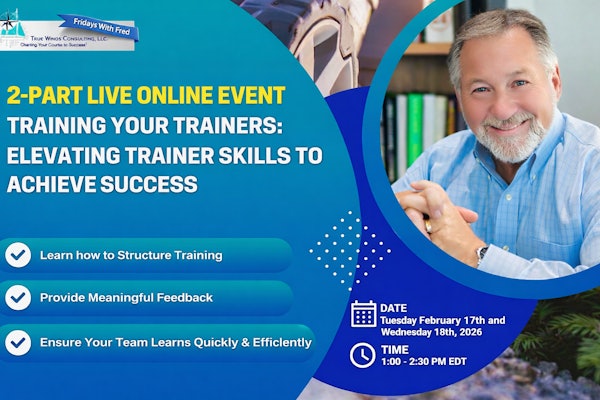

Flanked by managing director Ian Pratt on the far left and operations director Paul Grys on the far right, JCB employees joining in the Loadall celebration are, from left, Ian Vickery, Cliff Ferrie, Mick Smith, Dave Bailey, Nick Miller, Paul Stockley and Richard Jenkinson.

Flanked by managing director Ian Pratt on the far left and operations director Paul Grys on the far right, JCB employees joining in the Loadall celebration are, from left, Ian Vickery, Cliff Ferrie, Mick Smith, Dave Bailey, Nick Miller, Paul Stockley and Richard Jenkinson.Photo: JCB

JCB recently celebrated the production of its 200,000th Loadall telescopic handler.

Launched in 1977 as the JCB 520, the first Loadall was a two-wheel drive machine with a 21-foot lift height and a maximum lift capacity of 2.48 tons. Over the past 40 years, the JCB Loadall range has expanded to working heights of up to 65.6 feet and maximum lift capacities exceeding 6.61 tons.

JCB has updated the machine regularly through the years, introducing four-wheel drive, placing the engine to the side of the chassis to allow a lower boom-mounting position and offering multi-mode steering with equal-size wheels to improve maneuverability.

“From very small beginnings, the JCB Loadall has become a very important machine for JCB and for the construction and agricultural industries,” said Lord Anthony Bamford, JCB chairman. “’Revolutionary’ is often a word that is overused, but in the case of the Loadall, it is a perfect description.”

From that early two-wheel-drive 520 model, JCB went on to introduce the heavier-lifting 525 in 1980 and the lighter second-generation 520-2 and 520-4 in 1981. The 520-4 introduced four-wheel drive and larger rear wheels for improved traction on construction sites. These models were also notable for the introduction of JCB’s Q-fit implement carriage, which allowed operators to work with a range of buckets and attachments, including pallet forks.

Though known worldwide as Loadalls, it wasn’t until 1982 that JCB adopted that name for the machine. The same year, JCB introduced its own slick-shifting Synchro-Shuttle transmissions. Servo control levers were added in 1986 for easier operation, particularly in repetitive handling and loading operations.

JCB completely overhauled the Loadall concept in 1989 with rear-engine models incorporating multi-mode steering and equal-size wheels all round for improved travel comfort and maneuverability. In addition to front-end, two-wheel steering that made it easier to drive a Loadall down the road, drivers could enjoy turning in tight circles with all-wheel steering or even shuffling sideways in crab-steer mode to get out of an awkward corner or take the bucket edge along the side of a roadway.

However, by 1997, JCB discovered that moving the engine to a side-mounted position between the wheels could lead to further improvements. This allowed a greater reduction in the height of the boom pivot for even better visibility over the right-hand side and to the rear three-quarters while providing unmatched service access to the power unit and cooling pack.

JCB notes that the Loadall’s power and fuel efficiency got a boost in 2005, when the company introduced its own engine, the 4.4-liter Dieselmax. The following year, output was increased further for the engine’s debut in the side-engine Loadall.

Numerous advances in the machine and its engine followed.