“It’s one of the biggest challenges for small businesses,” says Tony Bass, landscaper-turned-consultant and co-author of The E-Myth Landscape Contractor: Why Most Landscape Companies Don’t Work and What to Do About It.

Statistics show that out of every five jobs, a typical contractor loses money on one, breaks even on one, makes about the expected profit on two and hits a financial home run on one.

“So if you do 50 jobs a year, that’s 10 bad jobs a year,” he explains. “If you can take those 10 bad jobs and replace them with good jobs, you’ll double your profit.” Here’s how you do it.

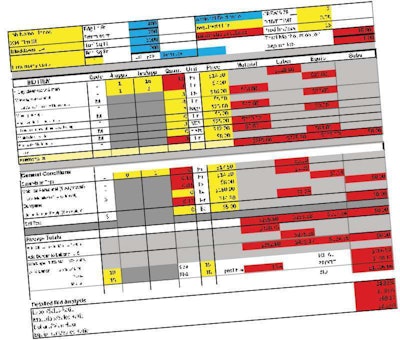

1. Develop an accurate general operating budget.

Profitable estimating begins with an accurate blueprint of how much it costs annually to operate your company. Review expenditures from previous years and/or use budget software to produce an accurate spending picture.

2. Account for overhead recovery.

Determine how much to mark up costs of services to recover overhead costs (administrative, fuel, etc.) and make a profit. “If you don’t recoup overhead costs, there’s not even $1 of profit in a job,” Bass says. Most smaller businesses underestimate overhead costs.

3. Develop a plan.

After listening closely to and writing down what a client wants, create a step-by-step plan and specifications for the project. Consult with vendors, subcontractors, equipment suppliers and employees to get ideas about the best way to do the job. Later, this plan and job specifications/measurements become a blueprint for your employees.

4. Estimate the cost of materials.

This is a straightforward cost to pin down. Examples: How many cubic yards of mulch are required? Accuracy here depends directly on the plan and project specifications you develop in step three.

5. Estimate subcontractor costs.

“This is the easiest part of the equation,” Bass says. Ask the subs to take a look at the project specifications and add their quote to your costs.

6. Use a production rate-based formula to estimate equipment costs.

It’s critical to know how much work each piece of equipment can produce in an hour. Example: How much turf can one of your mowers cut per hour?

If you don’t know, make a list of your equipment and perform time-and-motion studies on a variety of jobs.

7. Use production-rate data to estimate labor costs.

Just as with equipment, you need to know how much work employees can do in an hour with various tasks. Perform studies to obtain accurate data.

8. Submit a bid.

“Focus all of your energy and effort on getting the right price — the price that’s right for your company and right for your customer,” Bass says. Accurate estimating prepares and protects your bidding process.

9. Create a sales process to seal the deal.

“You must have a process for dealing with price objections that are sure to come,” Bass says. “You’re going to have to become a better salesperson and improve your overcoming-objections skills.” Example: Point out things that differentiate your company from competitors, such as certified employees, more on-the-job experience or newer equipment less prone to breakdowns.

10. You win! Now comes job-costing analysis.

Compare your estimate to the actual costs. “The most profitable companies spend as much or more time focusing on job costing than any other part of their business,” Bass says. “They know if they don’t keep good records of different tasks and how much time each requires, they’re not going to get better.”