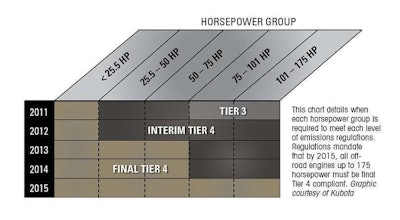

While emission tiers have been a huge part of the discussion for manufacturers since the U.S. Environmental Protection Agency (EPA) introduced the regulations in 1996, the effect on landscapers is just starting to be felt as Tier 4 Final requirements hit 25- to 75-horsepower diesel engines this year.

“The model year 2013 25-horsepower and larger engines are sophisticated,” says Mike Major, engineering regulatory compliance manager, Kohler Engines. “With this model year, Tier 4 standards have introduced low-particulate-matter (soot) limits. Engine manufacturers have adopted advanced controls and, in most cases, diesel particulate filters (DPFs) to meet the Tier 4 standards.”

Kohler designed their KDI line of diesel engines without a DPF, however, which they say cuts down on the purchase price and maintenance.

“Regardless of which engine and emission reduction technology is installed, it’s more important than ever to follow owners’ manual maintenance instructions,” Major says.

So, besides reducing the nitrogen-oxide

emissions and increasing the purchase price, there are other changes and improvements landscapers can expect to see with Tier 4 engines.

New Holland’s L220 skid steer meets Tier 4 standards with a diesel oxidation catalyst (DOC), instead of using a diesel particulate filter (DPF).

New Holland’s L220 skid steer meets Tier 4 standards with a diesel oxidation catalyst (DOC), instead of using a diesel particulate filter (DPF).What’s different?

While landscape business owners will see a cut in operating costs, equipment operators will only notice small changes in the machine’s performance.

“A new set of indicators and switches associated with the emissions controls have been added,” says Keith Rohrbacker, product manager, Kubota, “and operators should be sure to understand the manufacturer’s procedures for using automatic regeneration.”

The use of ultra-low sulfur diesel (ULSD) and low-ash engine lubricating oil meeting API-4 CJ-4 specifications are essential for ensuring proper functionality of modern exhaust after-treatment components, Rohrbacker continues.

“Operators should notice cleaner exhaust and less soot, as well as a quieter and smoother-running engine,” Major says. “They should also notice better, more consistent performance regardless of heat, humidity or other environmental conditions due to the advanced controls.”

Using a cooled exhaust gas recirculation (CEGR) system, the basic engine technology will stay the same. “There is no additive required, and the system does not require any change in the way the machine is operated,” Rohrbacker says.

The DPF does require periodic regeneration that varies depending on the engine load, however. “The filter offers a long life – more than 1,000 hours – but requires replacement eventually,” Rohrbacker says.

Why it’s important

“As Tier 4 equipment becomes more readily available, states and municipalities may begin requiring the use of emissions-friendly equipment,” Rohrbacker says.

While sustainability and lower maintenance have a higher upfront cost, landscapers can use these new technologies to better their business, fleet and environment.

“As more Tier 4 units are adopted and emissions and fuel consumption are reduced,” says Jeff Wilke, product manager, Kohler Engines, “landscapers should see better productivity as a result.”