When they are put under load, tons of stress are placed on everything from the hook at the end of the cable to the tiny gears deep inside the case that turn the electric motor’s spinning armature into brute pulling power.

If the winch isn’t maintained, inside and out – or it’s used improperly – components will fail.

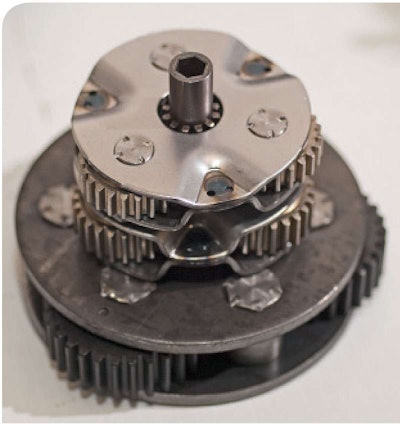

One of the areas winch users overlook when it comes to maintenance is the inside of the winch itself. More specifically, the gear sets and brake assemblies.

Winches, like any other complex tool, require maintenance. Those used in or around heavy construction should be taken apart, cleaned, and inspected at least once a year, much like hunters do with their rifles and shotguns.

This is particularly important on winches that have been operated in mud or have been submerged. Sealed or not, winches attract dust, sand, dirt and water, and those elements seem to find their way inside, especially older model winches.

Winches subjected to such operating conditions often result in gear sets that are packed full of a clay-like mixture of muddy water and grease, making gear movement sluggish and promoting corrosion.

Warn recommends that a submerged winch be taken to one of their certified service centers for disassembly, inspection and cleaning.

But contractors can save time and money doing the service in-house. It just takes some patience, attention to detail and good solvents to handle the task.

If the winch isn’t working at all and the problem has been traced to an internal parts failure (broken gears), the job is a little more involved – but easily handled by a shop mechanic.

Before disassembly, leave yourself plenty of room on a clean workbench to spread out the parts for inspection. Organize the components in the order they come off of the drive shaft or are stacked in the housing.

Pay special attention to the direction and order of the carriers and sungears that make the connections between planetary gear sets.

In a mid-frame winch like Warn’s M8000, take care when pulling the spring-loaded brake assembly from the drum that you are ready to place it in a similar diameter cylinder or have a clamp handy to keep the components together.

Most of the diagnosis for the gear sets will be visual. Look first for obvious broken pieces, corrosion, rust or sludge build-up.

If the malfunction issue is a build up of crud, clean, lube and test the gears using a moly extreme-pressure, low-temperature grease in the gear sets.

If the issue is a parts failure, such as a broken tooth on a planetary gear, then take extra care to thoroughly insect and clean the gear sets and case as you would any transmission that’s had a gear failure.

Disassembly-Assembly

There are lots of teeth to inspect in the sun gears, ring gears and planetary gears. When you find a problem, look for corresponding issues.

You are always looking for debris, but be especially diligent when you know a tooth or two is not where it is suppose to be because pieces from a broken gear can migrate to other areas and cause more damage.

Finally, inspect the gears for movement and slop; planetary gears should spin with finger pressure within their housing: Too much lateral play in bushings indicates a replacement is needed as well. (Worn bushings can cause more trouble than you might think.)

You can look up exploded-view diagrams of winches online to find the replacement part numbers. With part numbers in hand, you can order parts from the manufacturer or an approved service center.

Don’t cut corners on parts when rebuilding the winch. It’s better to put in new gear sets than to try and re-use worn gears that may still look OK.

Click through the slideshow below:

|

|

|

|

|

|

|

|

|

|

|

By Larry Walton / Editorial Services West