We teamed with Leland Garrison, service technician at Thompson Tractor in Birmingham, Alabama, for a quick lesson on the proper way to tension the tracks on a Cat CTL. Note that different brands of CTLs will have different ways to accomplish this task, so consult your owner’s manual or your dealer and follow their instructions for the brand of machine you have.

And don’t miss our video of this guide below where Garrison takes you through each step of this process.

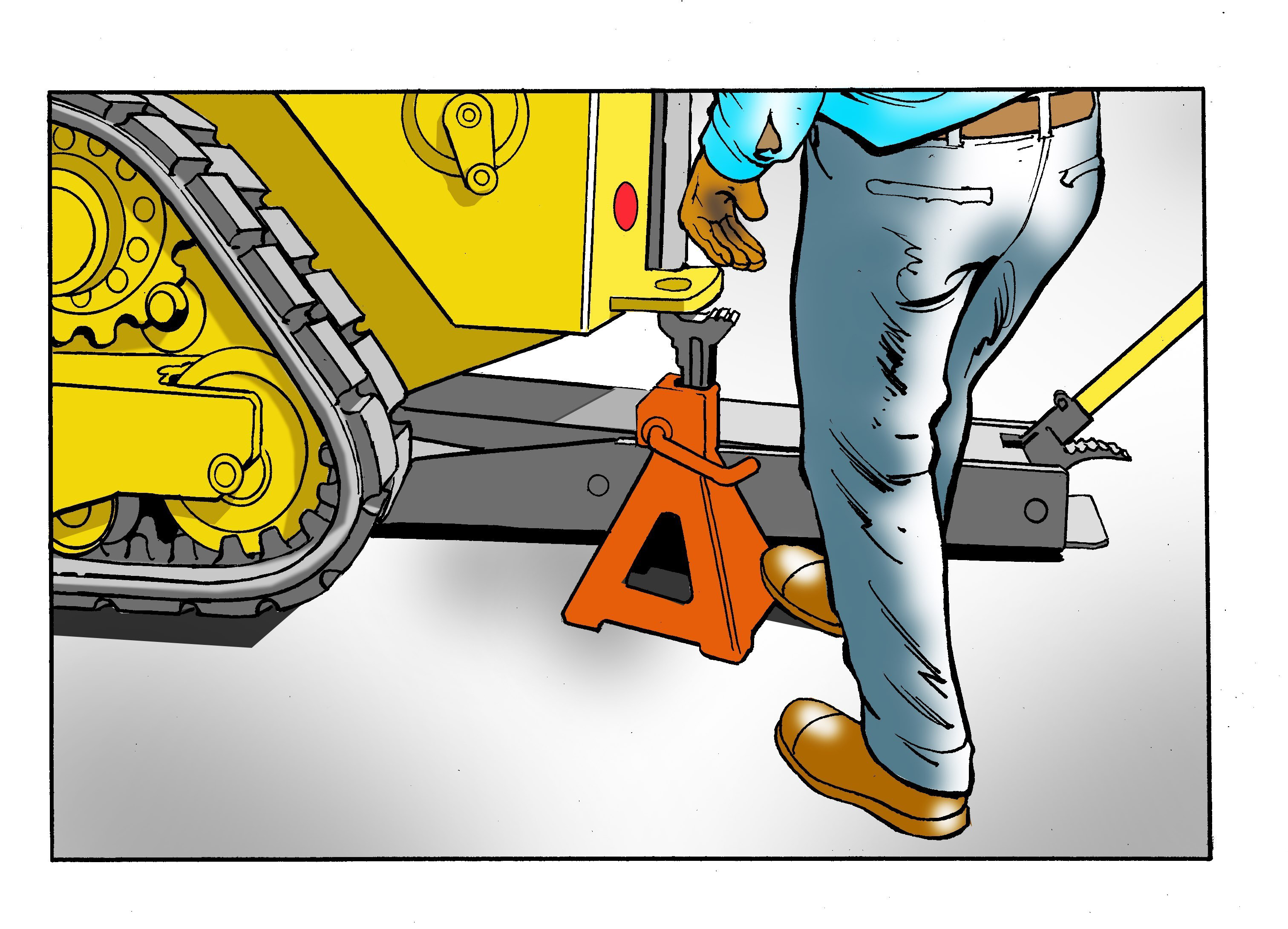

1. Jack up the machine Raise one side of the machine with a jack and place a suitably rated jack under the jacking points fore and aft on the machine.

Raise one side of the machine with a jack and place a suitably rated jack under the jacking points fore and aft on the machine.

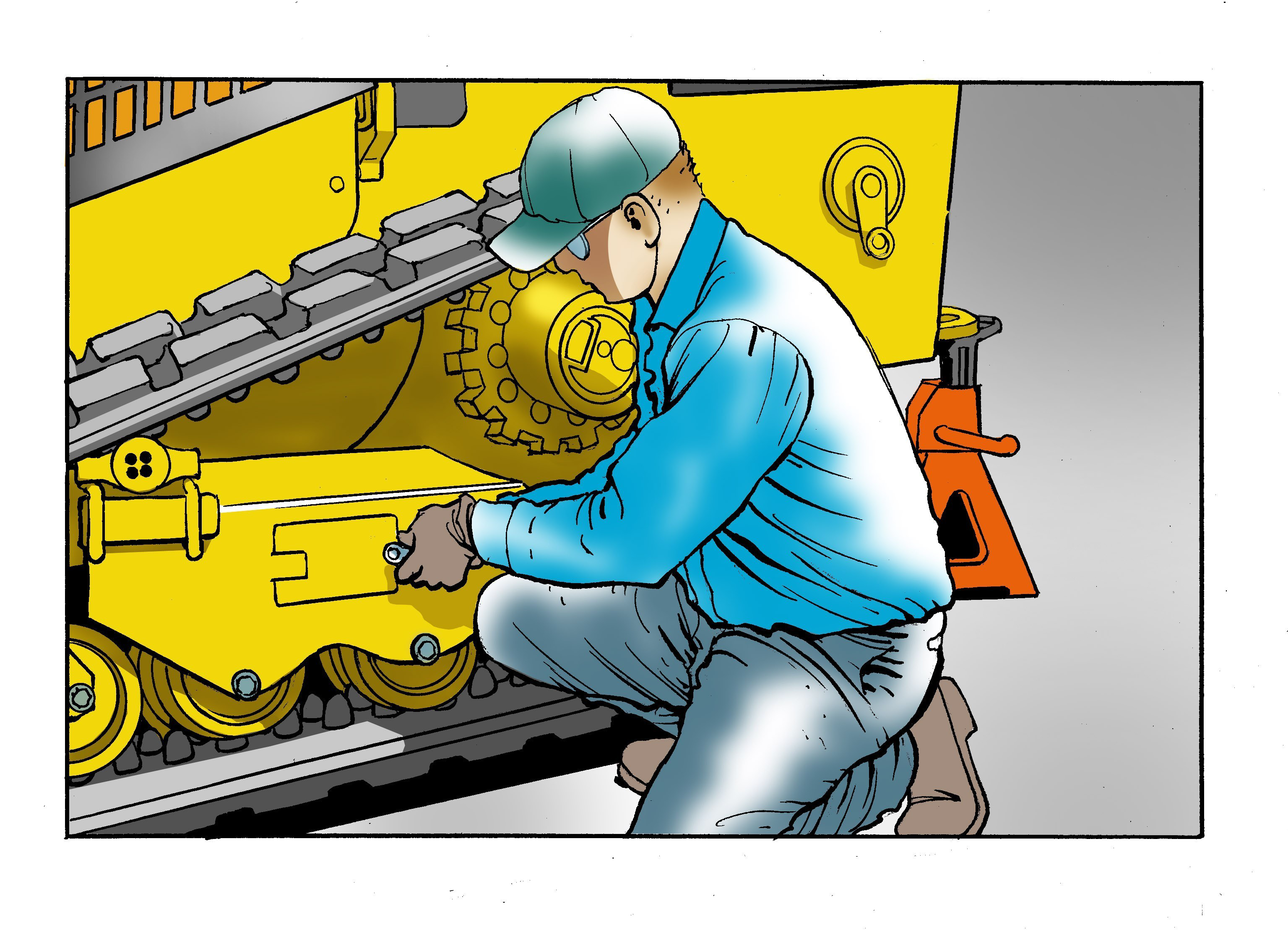

2. Remove the cover plate This will allow you access to a special grease zerk connected to a cylinder that increases in length to stretch out or tighten the track.

This will allow you access to a special grease zerk connected to a cylinder that increases in length to stretch out or tighten the track.

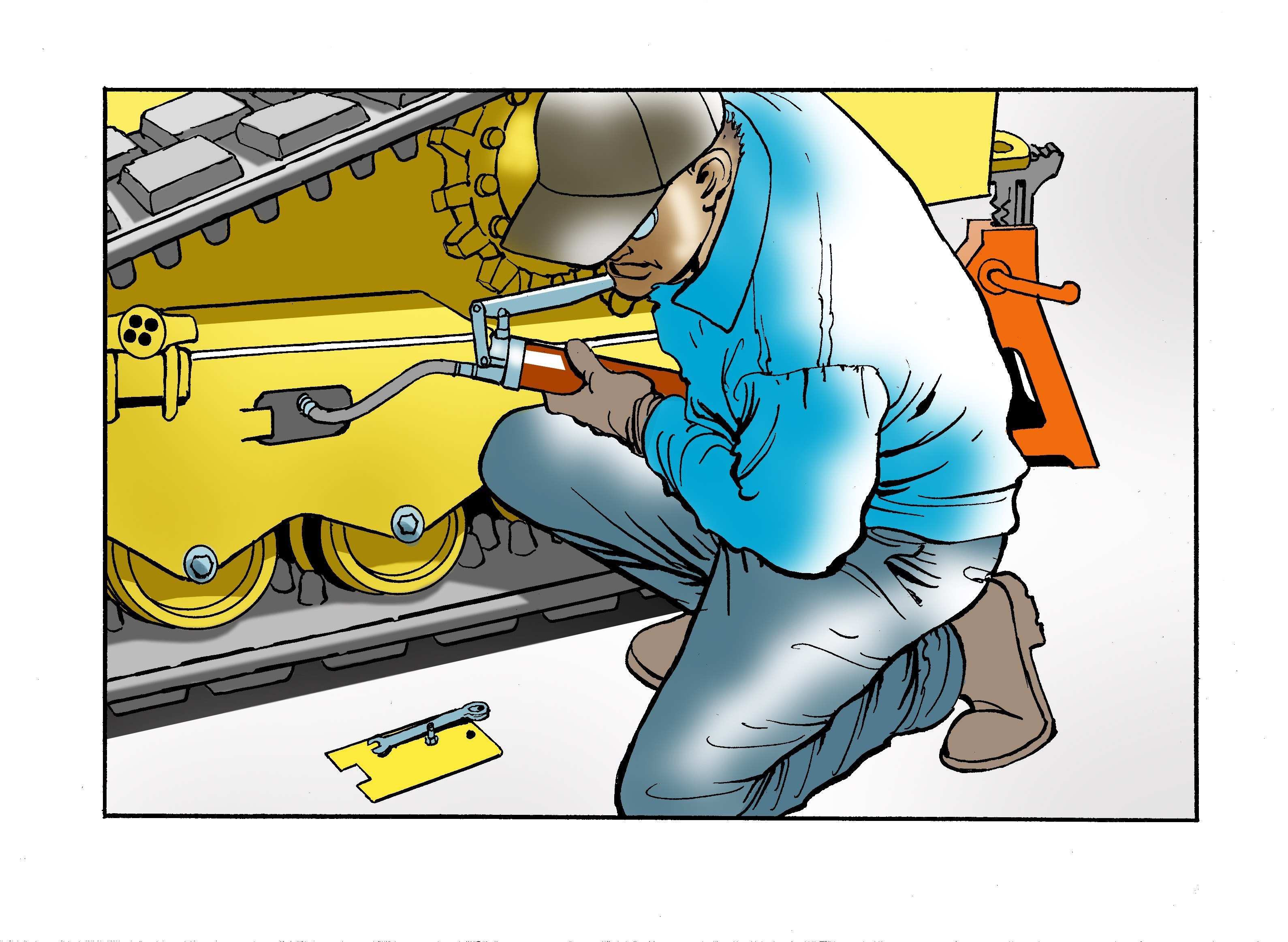

3. Add or remove grease Use a grease gun to add grease to tighten the track. Remove grease to loosen the track.

Use a grease gun to add grease to tighten the track. Remove grease to loosen the track.

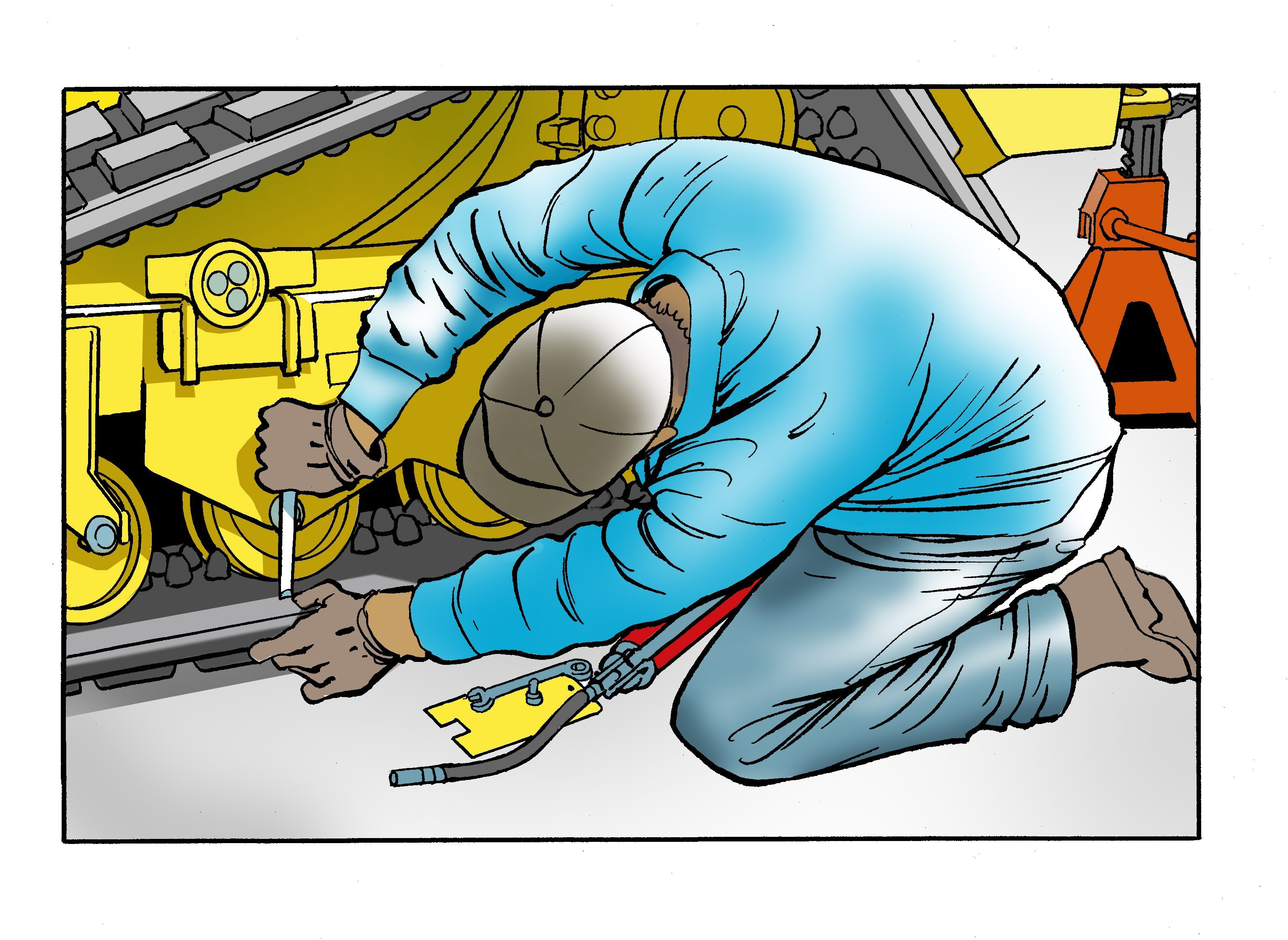

4. Measure the track sag The top of the lower run of the track to the bottom of one of the rollers should measure about 1 inch for optimal performance. Once that’s achieved, replace cover plate, lower machine and repeat on the opposite side.

The top of the lower run of the track to the bottom of one of the rollers should measure about 1 inch for optimal performance. Once that’s achieved, replace cover plate, lower machine and repeat on the opposite side.

EDITOR’S NOTE: Tom Jackson is the executive editor of Equipment World magazine, another Randall-Reilly publication.