E35i

E35iBobcat Company has introduced two Tier 4 compact excavators, which feature increased fuel efficiency and a new forward-mount instrumentation system.

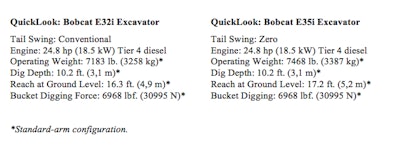

The Bobcat E32i and E35i are Tier 4 compliant and are placed in the 3-ton class of compact excavators.

The 24.8-horsepower excavators feature a direct-inject, 1.7-liter, naturally aspirated diesel engine.

E32i

E32iThe E32i conventional tail swing model and the E35i Zero Tail Swing excavator are ideal for operating in confined areas. Additionally, these M-Series machines can provide an up to 8 percent decrease in fuel consumption while operating in the machine’s Eco Mode.

Both models can be equipped with an optional extendable arm, which provides additional reach beyond the standard arm and allows for the use of a hydraulic clamp. The clamp can help in picking up and placing material such as rocks, landscaping materials and debris in site preparation applications.

The new forward-mount instrumentation system allows the operator to maintain awareness of machine vitals without losing focus on the task at hand. The system also improves ergonomics when the operator is interacting with the panel.

Additionally, the location of the panel aligns with the existing cab components and work group structures to maintain visibility to the attachment.

An available deluxe instrumentation panel includes an integrated keyless start system that provides for one assignable owner code and up to eight operator codes. The deluxe panel also provides an Eco-Mode setting, access to fuel consumption data, attachment operating tips and engine and hydraulic systems information. The deluxe instrumentation panel features multi-lingual functionality.

Like other M-Series excavators in the line, the two models include fingertip-activated control of the boom swing function and auxiliary hydraulic circuits. Features such as auto-idle throttle and auto-shift travel are standard equipment for the excavators. Auto-idle throttle contributes to reduced fuel consumption and easier communication between the operator and workers. The excavator will automatically idle the engine when the machine functions are not used for approximately four seconds. Auto-shift travel automatically shifts the machine out of high range without having to manually downshift.

The machines can operate a total of 13 attachments including augers, breakers, plate compactors, grading buckets, trenchers and rippers. The X-Change attachment mounting system allows the operator to change attachments as jobsite requirements change. Another option is the Hydraulic X-Change system, which allows the operator to change buckets without leaving the seat of the excavator.